Call us now

08045803118

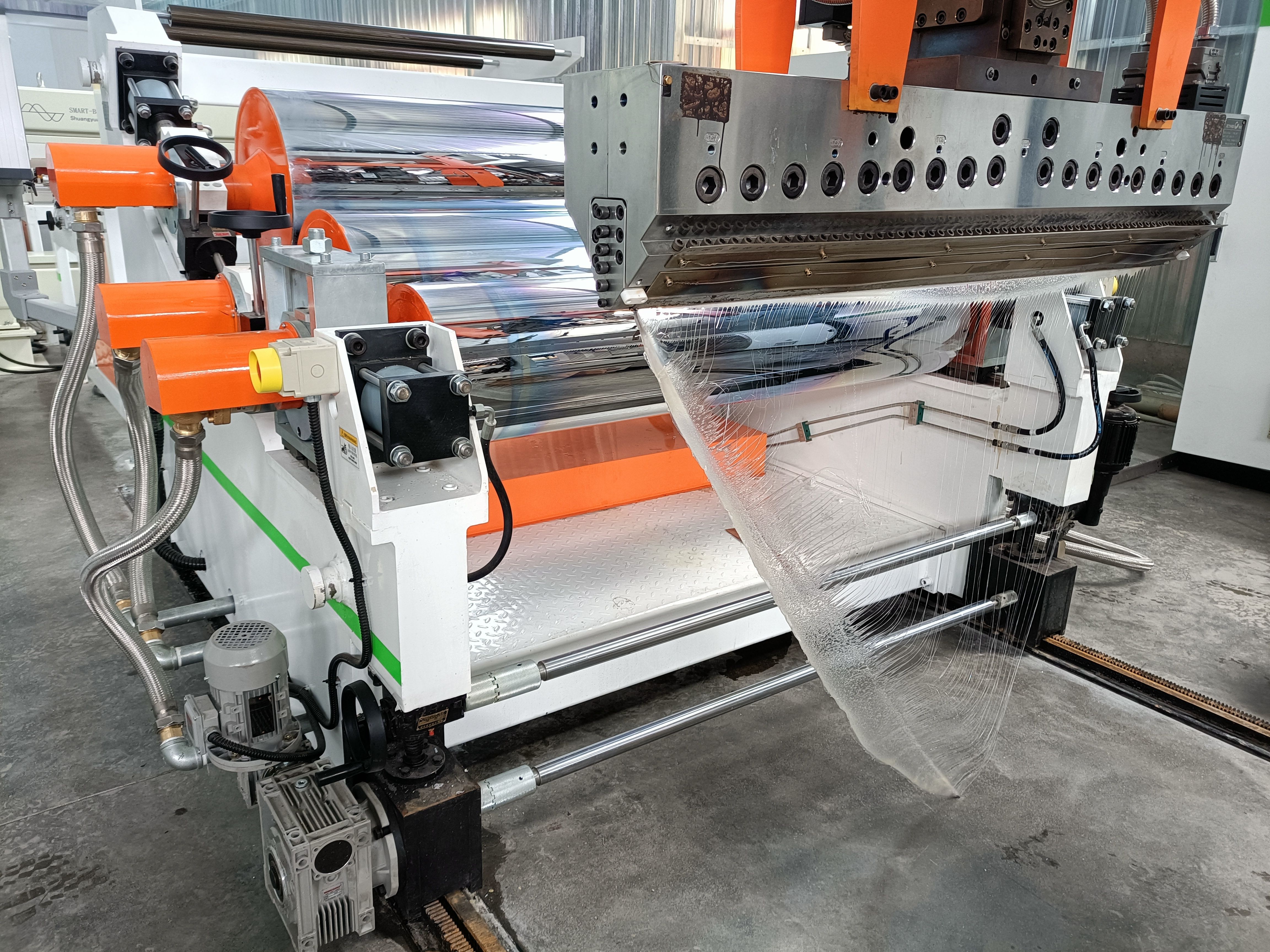

| Model | Extruder model | Products thickness(mm) | Main motor power(kw) | Max extrusion Capacity(kg/h) |

|---|---|---|---|---|

| Multi layer | LMSB75&36/40-1000 | 0.15-1.5 | 132/15 | 500 |

| Single layer | LMSB 75/40-1000 | 0.15-1.5 | 132 | 450 |

| Highly-efficient | LMSB 95&65/44-1500 | 0.15-1.5 | 250/75 | 800-1000 |

|

SIEMPRE MACHINERY PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |